Smeg Professional line GW6290 large dimension glassware washers

Your Location: Main>Euiqpment>Glassware Washer>Smeg Large Capacity>GW6290

GW6290 is a glassware washer designed to work from one to three independent and flexible washing levels. The washing chamber measures 680x670x1020mm (465L gross). Integrated compartment for the detergents. Possibility for washing, thermic and chemical disinfection (up to 95°C) and forced-air drying system with filter.

Specifications and Technical Features

GW6290 (art. 860682)

LARGE CAPACITY LABORATORY GLASSWARE WASHER (405 LITRES)

- washing up to 95°C – antibacterical thermal disinfection

- programs: 20 default + 20 custom

- multi-language TFT colour touch screen

- functioning protected by different levels password

- USB port for downloading washing cycles log

- peristaltic pump for liquid detergent

- peristaltic pump for liquid neutralizer

- possibility of installing up to 5 additional peristaltic pumps

- washing chamber and internal door made of AISI 316L stainless steel

- all internal piping made of AISI 304 stainless steel

- external panels made of AISI 304 stainless steel

- detergent cabinet made of AISI 304 stainless steel for 4 x 5 liters cans

- washing up to 3 levels

- external dimensions LxDxH: 900 x 800 x 1940 mm

- internal working dimensions LxDxH: 680 x 670 x 890 mm

- n. 2 independent washing pumps

- high efficiency drain pump

- built-in boiler for fast cycles preheating water

- cold water, hot water and demineralized water connections

- double electronic door lock system for user safety

- emergency opening system

- electrical connection: 3/N/PE 400 V – 50 Hz – 18 kW max

- 60 Hz version available

- without trolley

OTHER POSSIBLE CONFIGURATIONS

GW6290DS (art. 860683)

LARGE CAPACITY LABORATORY GLASSWARE WASHER (405 LITRES)

- standard equipment

- n. 2 motors forced hot air drying system

Machine optionals

- IC6010 – QUALITY WASHING CHECK CONDUCTIVITY SENSOR

- P36090B – PERISTALTIC PUMP FOR LIQUID ADDITIVES

- P46090B – PERISTALTIC PUMP FOR LIQUID ADDITIVES

- PAD2 – BOOSTER PUMP FOR NON-PRESSURE DEMINERALIZED WATER

- PAD2-60 – BOOSTER PUMP FOR NON-PRESSURE DEMINERALIZED WATER

- PAD2X – ST. STEEL BOOSTER PUMP FOR NON-PRESSURE DEMINERALIZED WATER

- PAD2X-60 – BOOSTER PUMP FOR NON-PRESSURE DEMINERALIZED WATER – 60 HZ

- WD-FLUX – FLOW METER FOR ADDITIONALS PERISTALTIC PUMPS

- WD-LAN60 – DATA COMMUNICATION CARD

- WD-LS3060 – DETERGENT LEVEL SENSOR

- WD-PRINTEINK – EXTERNAL IMPACT PRINTER

- WD-PRINTP6010 – CLEAN SIDE PANEL PRINTER

- WD-PRINTS6010 – UNCLEAN SIDE PANEL PRINTER

- WD-VDS – DUAL DRAIN VALVE

Technical Features

| GW6290 TECHNICAL FEATURES | All versions |

| Electronic control | microprocessor |

| Standard programs stored | 20 |

| Customisable programs | 20 |

| Display | touch screen graphic display TFT color (4.3’’with capacitive sensing) |

| Clock and calendar | yes |

| Tank internal temperature | from room temperature to 95°C |

| Accuracy | 0,1°C |

| Temperature sensors in tank | n° 2 x PT 1000 CLASS B IEC 60751 |

| Detergent and agents dosing system | max. n° 5, 2 installed pumps |

| Detergent level sensor | optional, max n° 5 |

| Safety lock | yes |

| Water heating | electrical – 18kW |

| Steam connection | no |

| Steam condenser | no |

| Alarm display | yes, acoustic and visible |

| Troubleshooting menu | yes |

| Program editing | yes, using customizable programs |

| Display languages | Italian, English, French, German, Russian, Spanish and Portuguese |

| AUXILIARY FUNCTIONS | |

| External sensor duct | no |

| Traceability | storage of data for 100 most recently run programs |

| RS232 serial port | yes |

| Cycle file download | yes |

| Cycle storage | yes |

| LAN connection | optional |

| Dirty/clean side printer | optional |

| Interior lights | optional |

| Water quality control(conductivity sensor) | optional |

| Sprayers speed control | |

| (heaven and background) | no |

| Automatic recognition cart | no |

| Pressure sensor circuit washing | optional |

| DRYING SYSTEM | |

| Drying fan | yes, n° 2 dryers – 220 m3 /h |

| Drying heating element | yes |

| Prefilter class C 98% | yes |

| HEPA filter class S 99,999% | optional |

| WATER SUPPLY (PRESSURE 1,5-5 BAR) | |

| Cold water inlet | yes, hardness max 42°f |

| Hot water inlet | yes, hardness max 10°f, max t 60°C |

| Demineralized water inlet | yes, < 30 μS/cm / 5 -8 ph, t max 60°C |

| Cold water booster pump | yes |

| Demineralized water booster pump | no |

| External water softner | outside, optional |

| Recirculation pump | n° 2 pumps of 600 l/min |

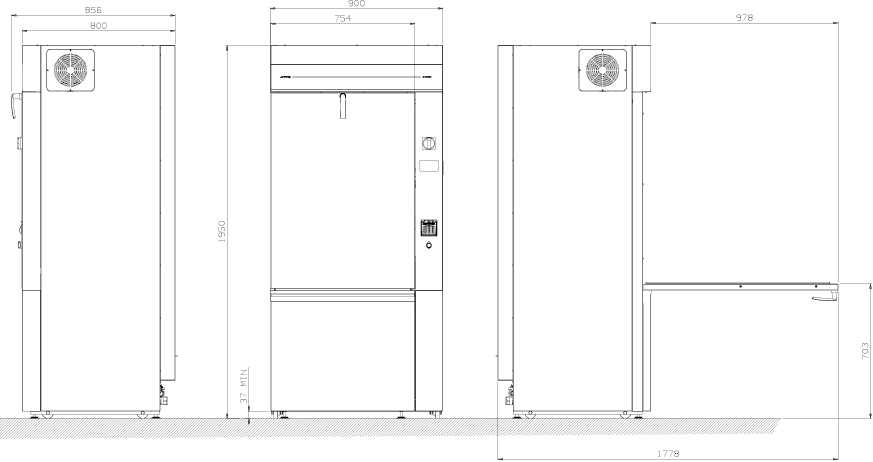

| DIMENSIONS LxDxH mm | |

| Outside (with built-in top) | 900 x 800 x 1940mm – drop down door |

| Inside (gross) | 670 x 650 x 835mm |

| Net weight (Kg) | 280 |

| STAINLESS STEEL | |

| Wash tank | AISI 316L |

| Exterior covering | AISI 304 |

| ELECTRICAL POWER SUPPLY | |

| Max. voltage/power | 3/N/PE 400V – 50 Hz 18 kW |

| NOISE LEVEL | Max 66 dB |

Possible Washing Configuration – GW6290 Series

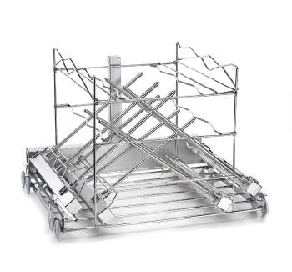

ONE INJECTION LEVEL

This configuration has one washing level suitable for washing glassware of large dimensions

Photo:

C61 with injection insert L685 (76 spigots available)

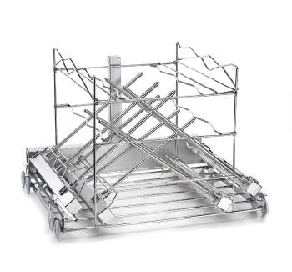

TWO INJECTION LEVELS

This configuration has two injection washing level suitable for washing glassware of small and medium dimensions.

Photo:

Level 1: C61 basic trolley with L680 direct injection system. Maximum useful height 260 mm, 76 spigots.

Level 2: C63 telescopic support with L685 direct injection system. Maximum useful height 440 mm, 76 spigots.

| DIRECT INJECTION SYSTEMS | MAXIMUM HEIGHT OF GLASSWARE (mm) | ROTATING SPRAYER

SYSTEM |

MAXIMUM HEIGHT OF GLASSWARE(mm) | |||||||

| 3°LEVEL | C63_L690 Telescopic base injection system | 130 | 390 | 130 | 720 | C62 Telescopic base with rotating sprayer | 95 | 360 | 95 | 790 |

| 2°LEVEL | C63_L680 Telescopic base injection system | 180 | 510 | C62 Telescopic base with rotating sprayer | 170 | 640 | ||||

| 1°LEVEL | C61_L685 Telescopic base injection system | 220 | 220 | C61 Telescopic base with rotating sprayer at the bottom of the wash tank | 390 | 340 | ||||

Accessories – GW6290 Series

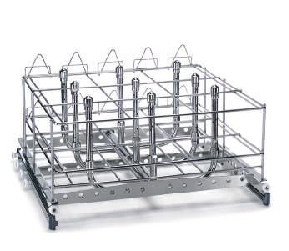

L680

INJECTION WASHING SOLUTION UP TO 76 MEDIUM AND SMALL GLASSWARE

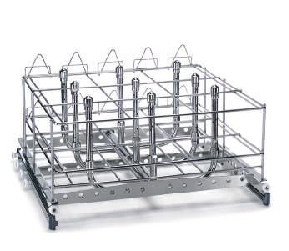

C65-I

INJECTION WASHING SOLUTION FOR 9 BOTTLES (LARGE SIZE)

L685CIL

WASHING SOLUTION FOR MAX 12 GRADUATED MEASURING CYLINDERS FROM 500ML TO 2000ML

LP6

SOLUZIONE DI LAVAGGIO PER 100 PIPETTE DI ALTEZZA MASSIMA DI 450MM

C61

1ST LEVEL BASIC CARRIER

Stainless steel first level basic carrier with grid. It is suitable for positioning various glassware up 790mm in height. The C61 basic carrier is also used to position the injection systems (L685/L680/L690) on level 1. The injector inserts are inserted into the guide rails of the C61: in this case, the maximum height of glass items must be 720mm.

C62

2ND AND 3RD LEVEL BASIC CARRIER

Stainless steel second and third level basic carrier with rotating sprayer. It is used on its own and is suitable for positioning glassware up to 360mm in height.

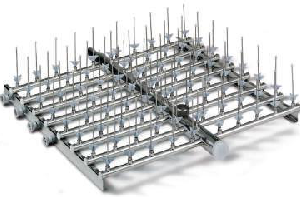

C63

2ND AND 3RD LEVEL BASIC CARRIER

Telescopic carrier for injection systems. The support is used to position the injection systems on levels 2 and 3. Suitable for positioning injection inserts (L680/685/690) directly in turn into the guide rails. Its flexibility allows the injection systems to be completely removed to simplify loading the glassware. Glass items max height 390mm.

C64

DRUM BASIC CARRIER – 1ST LEVEL

Stainless steel carrier to be positioned on the 1st level. With direct injection through specific nozzles. Suitable for washing drums with heights up to 530 mm and diameters up to 30 mm. Maximum useful height 835 mm.

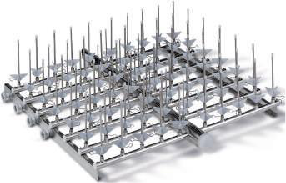

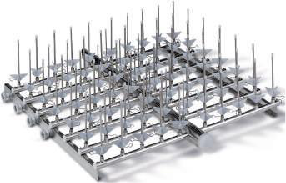

L680

UNIVERSAL GLASSWARE INSERT

Injection stainless steel insert for washing a max of 76 small and medium glass items. Spigots at the same height of 140 mm. Preferential use of the insert on the 1st or 2nd level over the specific carriers.

L685

UNIVERSAL GLASSWARE INSERT

Injection stainless steel insert for washing a max of 76 small and medium glass items. Spigots of differing heights make it possible to optimise loading of different sized glassware. This spigot configuration allows the system to be used on the 1st or 2nd level over the specific carriers.

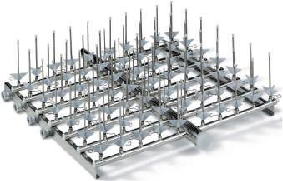

L690

UNIVERSAL GLASSWARE INSERT

Injection stainless steel insert for washing a max of 86 small glass items. Spigots at the same height of 110 mm. Preferential use of the insert on the 1ST, 2nd, 3rd level over the specific carriers.

LP6

PIPETTES WASHING INSERT

Suitable for washing pipettes with max in height 450mm and 8.5mm as maximum diameter. It easily hooks into the hydraulic grip positioned on L680 and L685.

C65-I

MIXED INJECTION CARRIER FOR BIG DIMENSIONS GLASSWARES

Injection stainless steel carrier for big dimensions glass items with drying system connection. Suitable for washing 9 bottles with max dimensions: diam. 175mm and in height 285 mm. Positioned on the lower level. C65S (not shown in the photo): same carrier for the upper level.

C636-I

MIXED INJECTION CARRIER FOR BOTTLES

Injection stainless steel carrier with drying system connection for washing max 36 narrow or wide-necked bottles of 250-1000 ml (max. diam. 90 mm, h 285mm).Positioned on the lower level.

C636S (not shown in the photo): same carrier for the upper level.

LM6-10U

DRUM INJECTION CARRIER

Injection stainless steel carrier with drying system connection for washing 5 drum max. of different dimensions. The customer can customize the carrier thanks to the spigots of variable in height and the repositionable rails.

L685CIL

INJECTION CARRIER FOR CYLINDERS

Injection stainless steel carrier for washing 12 graduated cylinders max from 500ml to 2000ml. Positioned on the lower level. L690CIL (not shown in the photo): Suitable for washing a max of 36 graduated cylinders from 300ml to 700ml. Positioned on the lower level.